Transmission Gearbox Model with Digital Tachometer

This project demonstrates the design and simulation of a gearbox transmission mechanism integrated with a digital tachometer. The gearbox highlights the mechanics of power transfer using multiple gears, while the tachometer provides real-time RPM monitoring.

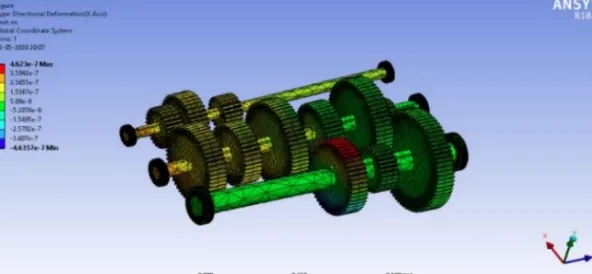

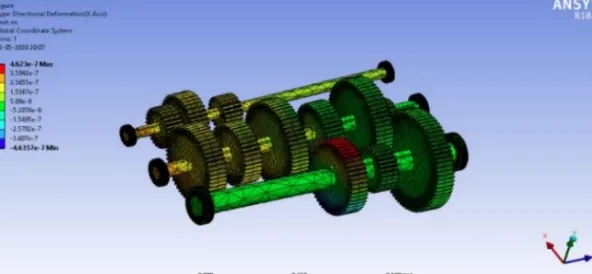

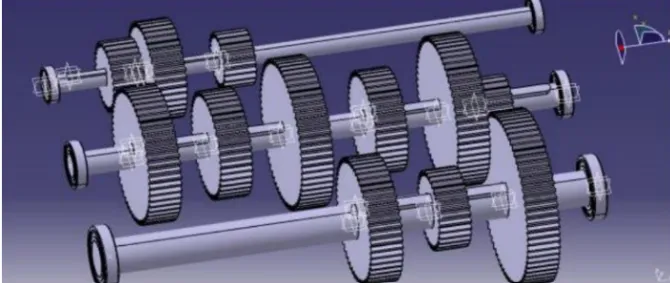

Simulation of Mechanical Transmission System

The gearbox was simulated to showcase power transfer through various gear configurations, helping visualize the impact of different gear ratios on performance, rotational speed, and torque.

Digital Tachometer Design

A digital tachometer was developed using sensors and microcontrollers to measure and display the RPM of the gearbox's output shaft, ensuring real-time performance feedback.

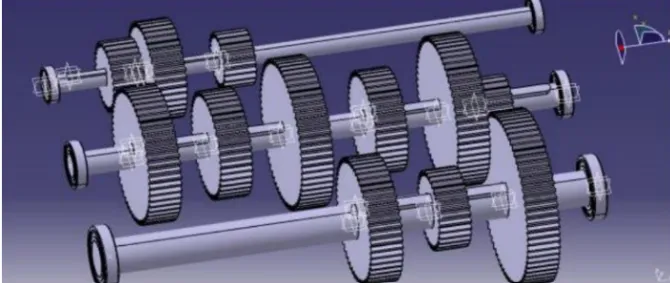

Mechanics and Electronics Integration

The project integrated mechanical components, such as gears and shafts, with electronics, including sensors and displays, to create a seamless system.

Gear Ratio Analysis

The system optimized gear ratios to enhance torque transmission efficiency, ensuring minimal losses and smooth operation under various loads.

Material Selection and Design

Materials like steel and aluminum were evaluated for strength and durability, while lightweight components were chosen for the tachometer to ease integration.

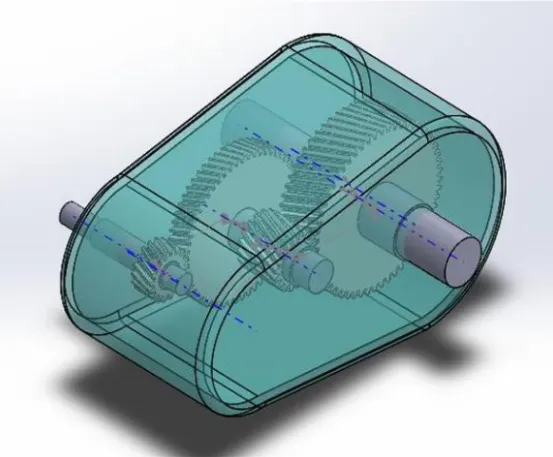

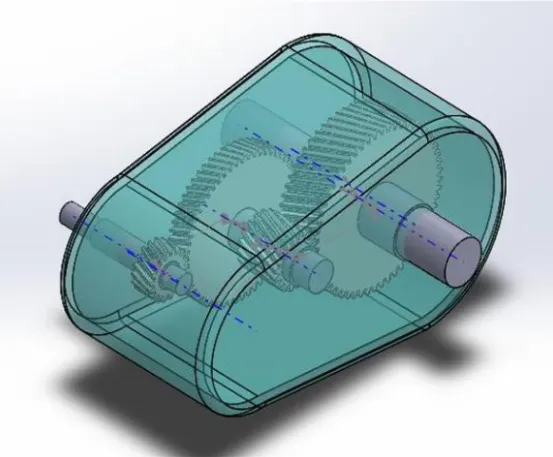

CAD Modelling and Simulation

The gearbox components were precisely modeled and simulated using SolidWorks, with emphasis on functionality and operational conditions.